ICAF System

Performance of the System

Compressed air foam (CAF) is generated by the combination of compressed air, water and foam concentrate in the right proportions, to create a homogeneous foam solution similar to shaving cream. CAF is delivered with high momentum through a fixed piping system, and distributed over the hazard via an approved discharge device.

The ICAF compressed air foam system is FM Approved as a local application extinguishing system for class B pool fires, spill fires and cascading fires. Full-scale fire tests have demonstrated ICAF to be an extremely effective extinguishing mechanism for flammable and combustible liquids, both miscible and non-miscible. The unique physical properties and texture of CAF allow it to form a stable and uniform foam blanket overtop the liquid surface.

The robust foam blanket developed during a discharge works at the fuel surface, creating an effective vapour seal to establish a physical separation between the fuel and the burning vapours. Because CAF is generated through aeration in a mixing chamber versus agitation at the nozzle, it has higher expansion ratios and longer drain times than conventional low-expansion foam systems. This translates directly into enhanced extinguishing and burnback performance.

Integrated Releasing

Control Panel

For applications where there is a risk of electromagnetic field interference, the FireFlex® ARC-1 releasing control panel, designed and testedto meet stringent EMI shielding requirements, can be used. The c-FM-us, MEA and CSFM approved panel is provided with a menu-driven programming including a specific program assigned at the factory.

This panel is compatible with many types of fire alarm and supervisory devices such as: linear heat detectors, spot type heat and smoke detectors, waterflow and release indicators, low and high air pressure switches and manual pull stations.

The panel also includes an alphanumeric display with up to 16 lines of 40 characters describing all the system conditions, and a set of red and yellow LED lamps individually indicating each of the alarm and trouble conditions of the system. Easy to operate control buttons are also provided to activate and operate the system’s various functions.

Water Supply

- ICAF system technology offers an important reduction in the water supply requirements compared to standard sprinkler or foam systems; the system can operate with a water pressure in the range of 3.45 to 12.06 bar;

- When fire pumps are required for system operation, they shall be designed and installed in accordance with NFPA 20, Standard for the Installation of Centrifugal Fire Pumps;

- The water supply shall be designed and installed in accordance with NFPA 24, Standard for the Installation of Private Fire Service Mains and Their Appurtenances;

- Water pressure vessels also available from FIREFLEX® Systems.

In all cases the water supply shall be capable of providing the required flow and pressure for the required duration as determined by FIREFLEX®’S hydro-pneumatics calculation program.

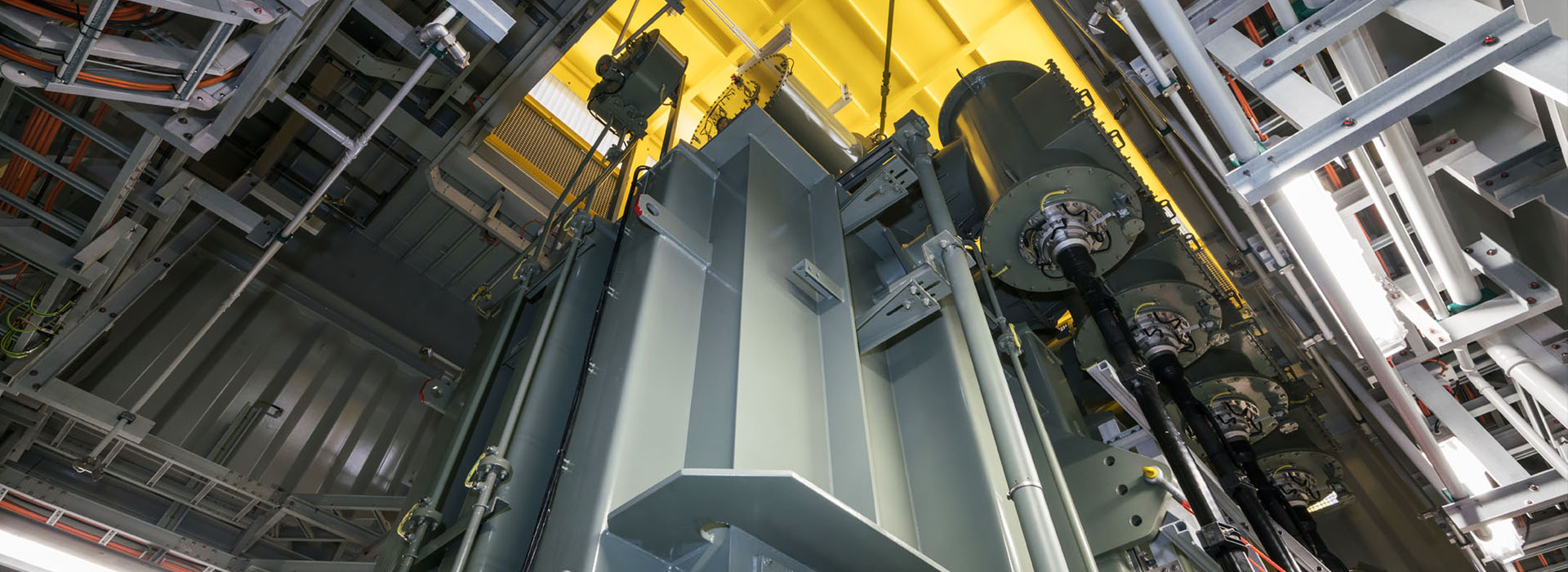

Air Supply

- Air is provided by DOT, CE and TC certified compressed air cylinders pressurized to 165 bar; each cylinder is supplied with a cylinder valve equipped with a safety relief disc which provides relief at 250 – 275 bar;

- Air pressure regulators are used to reduce the air supply pressure to 6.89 bar for the system operation;

- The cylinder bank pressure is supervised by a pressure transducer sending a low pressure supervisory signal when the pressure drops below the minimum pressure required to provide air supply for the specified discharge time;

- A safety valve is also used at the outlet of the air pressure regulator to protect the system from high pressure in case of malfunction, the maximum air operating pressure on the system side (downstream of the air regulator) is adjusted to 11.03 bar;

- The cylinder bank is factory assembled on a painted steel skid and includes high pressure tubing, manifold and hardware;

- The skid-mounted cylinder bank is available with single or twin pressure regulator assemblies and is available with up to 10 cylinders per bank.

The number of cylinders and regulators established at the design stage is based on both the maximum system flow and discharge time required for the largest single hazard protected or group of hazards that are protected simultaneously. FIREFLEX®’s program will take that information into account when calculating the system’s capacity.

Foam Supply

- Approved with standard AFFF and AR-AFFF foam concentrates;

- Foam concentrate is stored inside a normally non-pressurized stainless-steel pressure vessel type tank stamped according to ASME Section VIII Div. 1;

- Foam storage tanks are built to order and come in various sizes from 19 to

1892 liters; - Storage tank maximum working pressure is 10.34 bar;

- The tank is supplied with a safety relief valve set at 9.31 bar for protection against over-pressurization;

The foam storage tank is factory assembled and includes valves, trim and hardware. Manual valves are provided to fill the tank with foam concentrate and to release the air pressure after a ICAF discharge. A sight gauge assembly is also provided to allow visual verification of the normal foam concentrate level.

ICAF FM APPROVED DISCHARGE DEVICES / NOZZLES

Nozzle TAR-225

Foam-Powered Oscillator

Ceiling Nozzle Configuration

The TAR-225C is an open-type ceiling nozzle used for area protection of flammable or combustible liquids spill or pool fire hazards and is specifically designed to effectively distribute CAF over a remote area.

Located at the ceiling level the ICAF Nozzle is designed to discharge CAF in a 360° radius over a maximum area of 150 ft2 (13.9 m2) when used on hydrocarbon liquids and 100 ft2 (9.29 m2) when used on polar solvents.

Specific Hazard Configuration

The TAR-225L is an open-type directional nozzle which is specifically designed to discharge CAF over exposed horizontal or vertical surfaces of specific equipment, and is effective on cascading fires.

The TAR 225L nozzle spacing shall be based on the spray pattern design principle. Nozzles shall be spaced and aimed so that their spray patterns will cover all surfaces adequately.

Foam-Powered Oscillator

The FPO is an open-type oscillating nozzle that is specifically designed to project CAF horizontally over a wide area. It is an effective discharge device for low-level protection. The CAF can be delivered via a 90° or 180° arc of oscillation with discharge range up to 92 ft. The FPO nozzle is self-propelled by the CAF discharge and does not require any electrical or hydraulic connection, considerably simplifying installation.