Loading and unloading for Tankers

and / or Railway Wagons

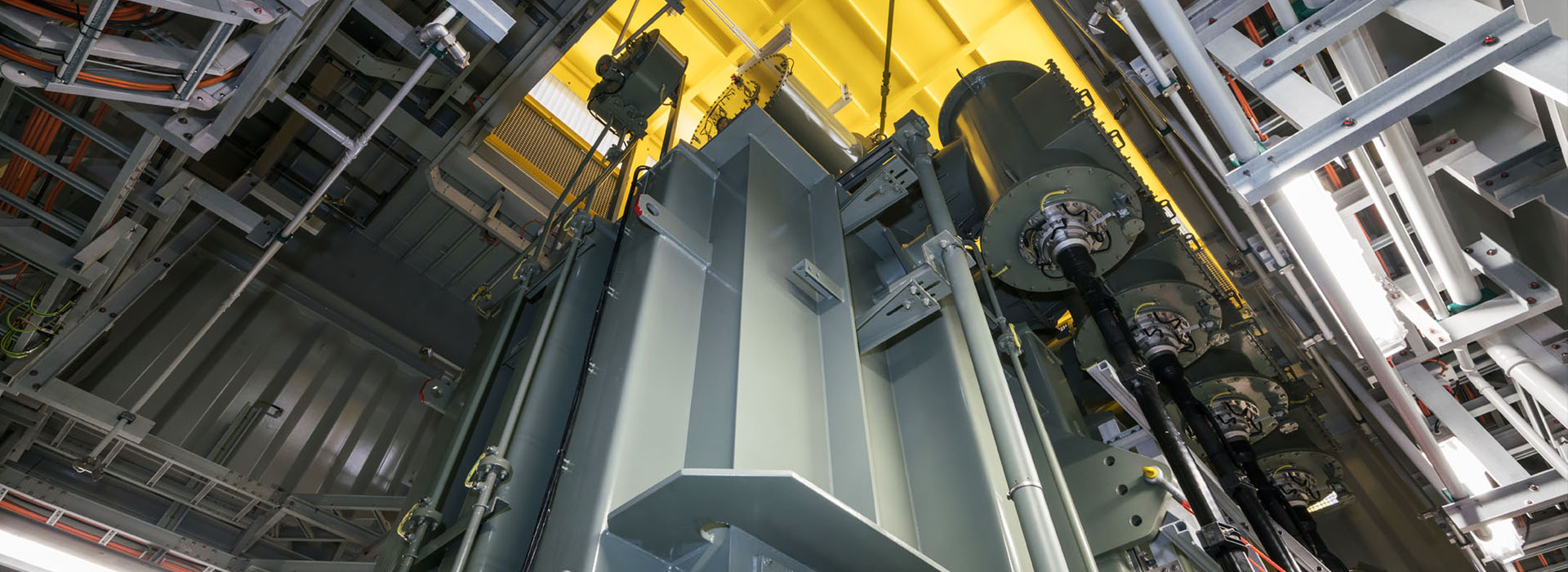

Different fire scenarios are possible with regard to loading and unloading sites. The CAF system mainly focuses on fighting a pool fire at the loading and unloading site. This is a result of a failing connection or the rupturing of a hose or a transport pipe. Generally, a fire due to instantaneous failure of the tank is an unreliable scenario. The area that is sensitive to this scenario should be in the coverage area of the CAF system. So, there is always a relationship between the size of the CAF system and the size of fire extinguishing and product collection. Because the drainage times of the CAF system are known (FM approval), the required extinguishing water collection can be adjusted to the water released from the foam which has been applied to the relevant area.

Fire Hazards – The fire hazards at loading/unloading platforms, where activities involving flammable liquids pose a risk for a spill fire or truck fire on the loading area. The daily site operations involve transporting, dispensing and storage of the liquids in vertical and horizontal containers on the load-ing platforms. The flammable liquids are bottom-loaded or top-loaded from the containers. The hazards are congested with machinery, equipment & piping and the industrial site is in close prox-imity to residential & commercial developments

Two design options are normally considered to provide active fire suppres-sion/extinguishing systems (water-based, foam-water or CAFS) or passive fire protection with fire separations. The preferred design approach would, in addition to limiting fire spread, have to limit the run-off of fuel and fire water or foam.

he pump plate or pump sump (in a number of cases) with this CAF type of system can therefore also be secured within this strategy. Normally the CAF system is activated fully automatically by means of a fire alarm system. In addition, the system can also be implemented with a manual activation control in order to prevent any spurious releases.

NFPA 11 (2016 edition, chapter 7) describes the application of Compressed Air Foam. The design of the CAF system must meet the requirements set out in this chapter of NFPA 11. For situations where NFPA refers to the use of ‘listed’ equipment (such as the mixer), the FM approval is used. The FM approval, in combination with the conditions stated therein with regard to projections, application rates, used materials and the like, covering all elements that are mentioned in the NFPA 11.

In accordance with the requirements in the NFPA 11, the CAF system must function completely automatically for at least 10 minutes. The design in this specific situation must pay attention to the fact that it is possible that a full tanker or.wagon needs more than 10 minutes to empty. The CAF system will extinguish the fire but there is a possibility that because of the continuous interruption of the foam layer at the location of the outflow opening (typical DN 80 for a tanker) there is a possibility that a small fire will remain.

This is a fire that can be extinguished relatively easily with small extinguishing agents or portable fire extinguishers. Because the remaining liquids are either drained or covered under the foam layer, a new escalation of a fire is not likely. Of course, the spraying time of the CAF system can be extended if it turns out that it takes longer to get trained personnel to access the location that can take care of this last check and possible deployment.