Protection of group II small Helidecks / Aircraft Hangars

Because of the current trend towards small regional airlines and corporate jets usage for point to point air travel, many airports are getting new helidecks / aircraft hangars built. These smaller jet planes are often stored and maintained in smaller hangars, typically classified as Class II Hangars. This fast growing industry segment makes that more and more hangars are being built or re-commissioned for this usage, along with their need for adequate fire protection.

NFPA-409 is the standard mostly used for the design of AFFF Foam Systems in these applications and currently defines these smaller hangars as being part of Group II, having an aircraft access door height of 8.5M or less and a single fire area not exceeding 3716M². AFFF stands for Aqueous Film Forming Foam and is a fire fighting foam widely used to extinguish fires in hydrocarbon fuels.

At the moment, NFPA-409 offers 4 options to the designer when designing the proper fire protection system for these Group II Hangars:

- They can be designed using the same criteria as Group I Hangars, which include an automatic Foam-water deluge type sprinkler system. If air aspirated devices are installed, the design discharge rate can be reduced from 8.12 L/min/M² to a minimum of 6.5 L/min/M² of floor area.

- A combination of automatic sprinkler protection and an automatic low-level, low expansion foam system can also be used.

- A combination of automatic sprinkler protection and an automatic high expansion foam system is also an option.

- Finally, a closed-head foam-water sprinkler can be installed.

Problems

with the use traditional technologies

As described above, all four traditional methods of protection require an already available water supply source of large capacity that is often simply not available at these smaller regional and remote airports. In many locations, the water main loop either has to be brought near the new hangar, with the associated infrastructure costs or as is often the case, adequate water pressure and quantity is simply not available!

Other times, water is available but the total water requirement of these four types of foam-water systems require the use of expensive high capacity water pumps, either electric or diesel powered, with their associated hardware. Drainage requirements for such large volumes of water are often totally overlooked and can be quite substantial.

Due to the very competitive business environment owners of small commercial operations and airlines work in, the investment necessary to fit such systems quickly becomes prohibitive and the hangar often ends up without adequate fire protection or, as is often the case, only partially protected. Insurance premiums rise and the local authority having jurisdiction often hounds the owners to do something about this added risk.

A new

solution is available

Although ICAF is not included in NFPA-409 at this time, numerous full-scale Class B fire tests have clearly demonstrated that ICAF extinguishing systems perform at an equivalent level to foam-water extinguishing systems in controlling and extinguishing Class B fires. Based on this, when water supply was an issue, Authorities Having Jurisdiction (AHJ) have approved the use of Compressed Air Foam as an acceptable alternative.

The designer should confirm with the AHJ on his project that ICAF is accepted as an alternative before proceeding with the design. When it is, a fifth solution is now available to him, providing better fire suppression capabilities with only 25% of the water requirements!

This new FM Approved AFFF foam system is designed using NFPA-11 TIA #05-1. Compressed Air Foam (CAF) only requires a design density of 0.04 gallons of foam solution per minute, per square feet (1.6 Lpm/sq.m.) of floor area. And at this reduced water requirement, ICAF systems still manage to provide better suppression capability than the four other traditional systems. Furthermore, the quantity of foam concentrate is also reduced by using the ICAF Systems since its high efficiency is achieved while using only a 2% concentration of AFFF foam concentrate instead of the usual 3%!

On a typical aircraft hangar project with water supply issues, the total savings over the traditional systems represents up to 35% of the total project budget value on infrastructure! This fact alone has convinced many owners of hangars to go ahead and specify an ICAF System for installation in their premises.

Design

with ICAF

ICAF Systems are of the open pipe, deluge type and are designed based on the surface coverage of the discharge nozzles. They also require that flows and pipe runs be balanced.

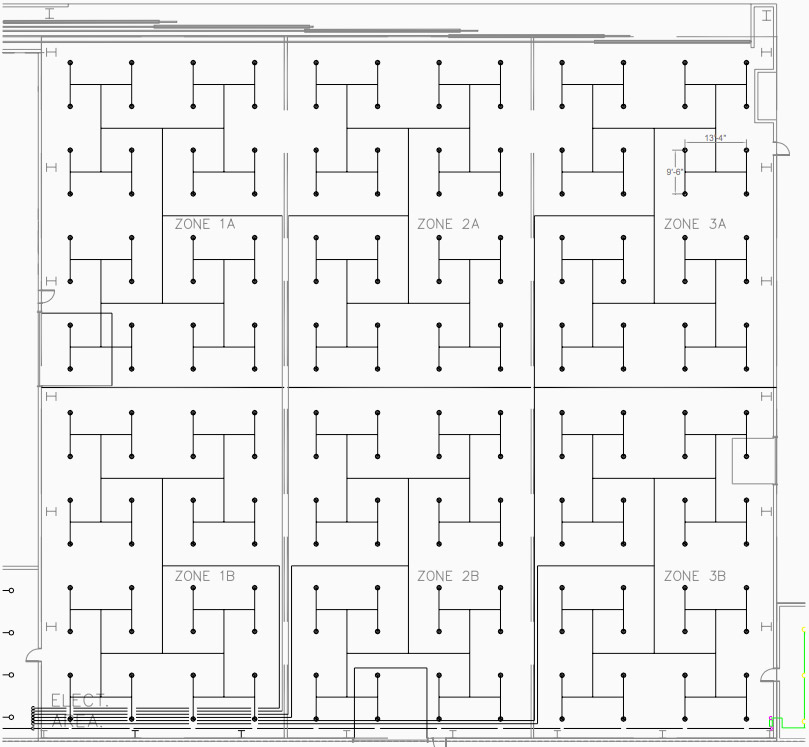

For a typical hangar measuring 25,600 sq.ft. (2,378 sq.m.), using FireFlex Systems ICAF Systems Design Manual, we can determine that to protect the whole floor area of this hangar, with a nozzle spacing of 12′- 3″ x 12′-3″ per TAR-225C Nozzle, it will take a quantity of 192 nozzles to adequately cover the whole area.

Being limited to 32 nozzles maximum per CAF mixing chamber, the system needs to be split into 6 mains in 3 fire zones, distributed among three integrated cabinets connected to a single common foam supply tank and bank of compressed air cylinders.

In this example, water flow required for the ICAF System was calculated at 1,200 gpm compared to 4,700 gpm for a standard foam-water deluge system that would also have needed 252 nozzles to protect the same hazard!

Project

Scope of Work

Figure 1 (see below) shows a typical ICAF System installation with its grid of discharge nozzles installed at the ceiling level. The balanced flow piping is also much simpler to install and of smaller diameter than the equivalent foam-water system, reducing the costs for the installing contractor.

The foam concentrate is stored in a non-pressurized tank and does not use bladders or complicated inductors and trims. The entire foam trim is even factory built in user-friendly cabinets!

A bank of high pressure compressed air cylinders is supplied to provide the pressure to the system so the existing water pressure can often be used to feed the system.

Figure 1

Typical nozzle distribution for a 25,600 sq.ft aircraft hangar

Conclusions

Fire protection designers now have an additional weapon in their arsenal of fire combat tools. The ICAF technology is emerging as an environmentally friendly solution for protection of aircraft hangars and similar hazards.

The selection of the ICAF System represented the ideal solution for the protection of this type of aircraft hangar which otherwise would perhaps have not been protected at all, or at much greater costs to the owner. Not only was the installation substantially less expensive but it also prevented major infrastructure modifications and downtime to the existing facility. Such considerations are often neglected by the designer in the feasibility studies for the installation of fire protection systems for aircraft hangars.

Considerations should also be made for the water supply portion of the installation. Indeed, the supply and installation of fire pumps (vertical turbine or diesel powered), water storage tanks and redundancy would have increased the costs dramatically! Those were not required by using an ICAF System to protect the facility.

Containment, collection and drainage of all that water is also an issue that is often neglected and for applications in remote or northern regions is simply not possible. Installation of the ICAF System proved to be easy for the contractor, using standard sprinkler piping and hangers and at the end, and offering better fire protection without the associated water damage.

Should you have questions regarding this application or any others involving helidecks / aircraft hangars, contact SIRON Compressed Air Foam. Our engineers will work the project out with you and find the best layout for your specific application.