Protection of High Voltage Power Transformer

In our modern societies we are use a lot of transformers technology in our day to day life to the point where we have grown to be totally dependent upon electrical power, both in our private lives and in most commercial or industrial activities.

The electric power industry has installed power substations in their distribution grids to accommodate the ever increasing demand for dependable power with their rows of large high voltage power transformers. Many precautions are taken to safeguard them against failure because when all power fails, customers complain, revenues are lost and medical emergencies can even happen.

One of the risks these large transformers are subject to is fire. Although the manufacturers of these oil filled transformers are building them with many imbedded safety features, when they fail they often produce very large fires that are very hard to extinguish and provoke environmental damages with the release of thick black toxic smoke and spilling of transformer oil.

This is why more and more utilities are installing fire protection systems to protect their investment and to prevent such fires. Containment curbs and runoff water catch basins are also built around the transformers to prevent oil spills in case of problems.

Problems

with the use of traditional technologies

When they are protected, most high voltage power transformers have a deluge sprinkler system and designers use NFPA-15 as a guide to design a system that will cool off the transformer and eventually, extinguish the fire.

Typical design calls for a grid of open type deluge/spray nozzles to be installed all around the transformer. A typical system will use about 44 of them and will be designed to spray about 1,900 L/min of water for a duration of one (1) hour. That is a lot of water!

NFPA-850 for Power Plant Design goes even further, requesting water spray duration to last a full two (2) hours! But minimum provisions for drainage are specified to be only large enough to contain the spill from the largest single container of any flammable or combustible liquid in the area and for fixed fire suppression systems operating for a minimum of 10 minutes!

A lot of power substations are located in remote areas, or on the outskirts of towns where water is often not readily available in these large quantities. Water reservoirs have to be built (often underground) to accommodate this large demand. They require an initial investment that is fairly high for the utility company and they also need regular maintenance, factors that are rarely included in the contractor’s fire protection proposal.

Even when water is available in these quantities, powerful fire pumps will be needed to provide water at a sufficiently high pressure to achieve the goals of the fire protection system. Infrastructure costs for the utility company rise rapidly, to the point where some of them don’t protect their transformers at all and will simply provide passive protection measures such as firewalls.

Then, when a fire happens, so much water is discharged by the fire department on the flaming transformer to cool it and control the fire that soon, the curbs built around it overflow and hot transformer oil is spilled around, compounding the problem with the possibility of burn back and now creating an environmental problem that also has to be dealt with.

Design

with ICAF

A solution to these problems is now available using FireFlex Systems ICAF Integrated Compressed Air Foam system for fixed piping network.

This new FM Approved AFFF foam system allows the designer to alleviate many of these potential problems while providing superior fire protection (AFFF stands for Aqueous Film Forming Foam and is a fire fighting foam widely used in the industry to extinguish fires in hydrocarbon fuels such as transformer oil).

NFPA-11, states that where fixed spray type systems are used to protect 3 dimensional equipment like power transformers, the minimum density shall be applied over the projected area of rectangular prism envelope for the equipment and its appurtenances. Furthermore, system discharge duration shall be designed for a minimum period of 5 minutes (art. 7.16).

Using FireFlex Systems FM Approved ICAF Design Manual, the designer will locate a grid of local application nozzles to cover the transformer’s surfaces, based of the published square area of coverage versus mounting distance ratio of the TAR-225L Nozzles. But because of the coverage area of each nozzle and the dense texture of Compressed Air Foam, the spray nozzles grid all around the transformer uses much less nozzles than the equivalent deluge system.

The quantity of foam concentrate is also reduced by using the ICAF Systems since its high efficiency is achieved while using only a 2% concentration of AFFF foam concentrate instead of the usual 3%!

For a typical high voltage power transformer, such as the one shown in table (see below), ICAF Systems are designed at the much lower water flow rate of 360 L/min and will need a grid of only 16 nozzles. Because of the much shorter discharge time of 5 minutes, the total water quantity will be dramatically reduced; only about 1,800L of water will now be needed to completely suppress the fire while providing protection against burn-back, which deluge systems cannot do.

Immediately, one can see that the need for large reservoirs, pumps, containment dikes etc. is not necessary anymore and the utility company is now making large savings, while having a much more efficient fire protection system protecting its investment.

This small amount of water, foam and transformer oil can now be easily pumped after a fire and treated. Possible of damages to the environment are reduced significantly because the risk of overflowing water and transformer oil over the containment curb is eliminated.

Project

Scope of Work

Typically, a power transformer fire will involve both a cascading fire from the oil coming from the expansion tank situated at the top of the casing and a pool fire in the curb surrounding the transformer, which makes them very difficult to extinguish.

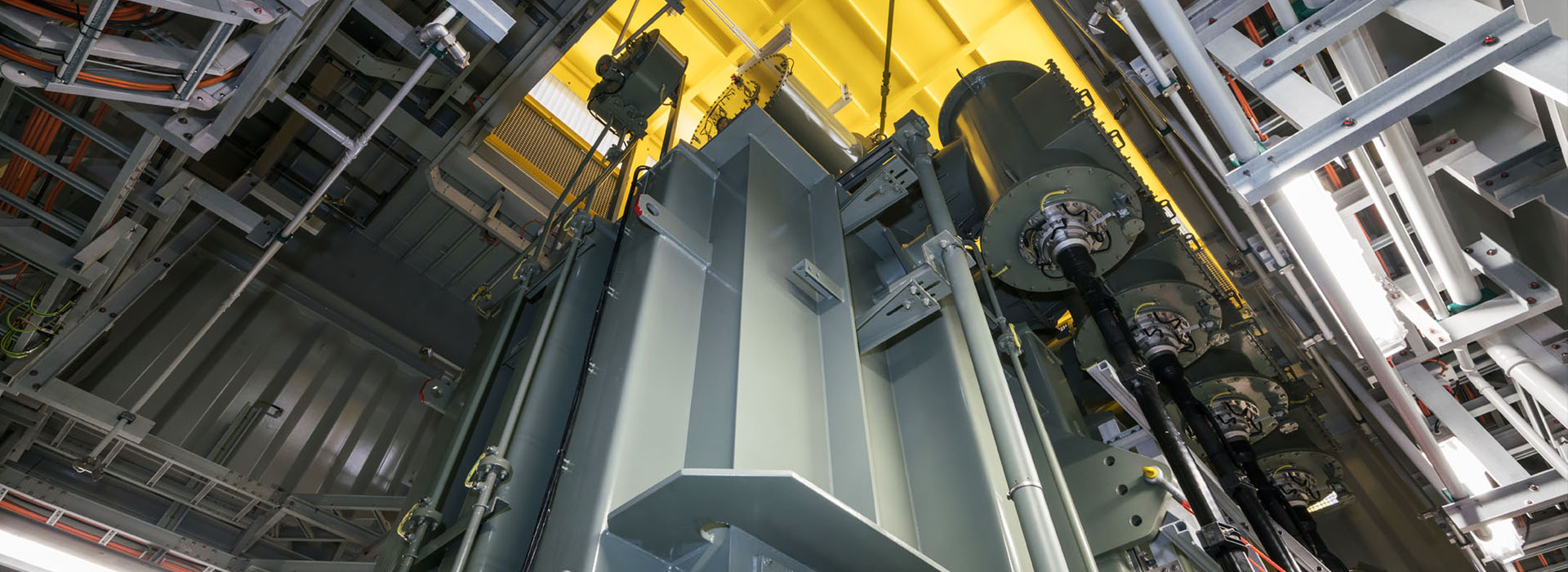

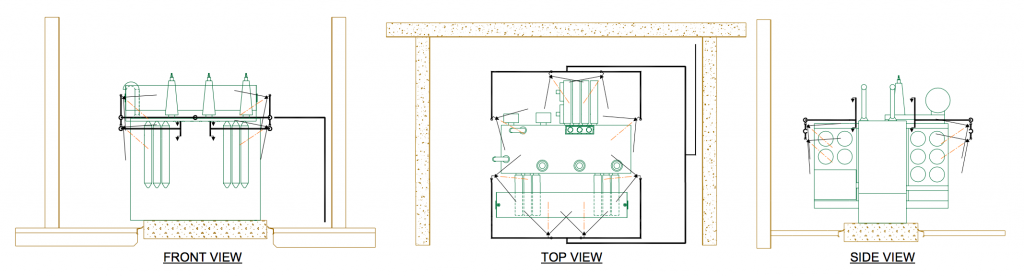

Figure 1 (see below) shows a typical ICAF System installation with its grid of discharge nozzles installed around the transformer. A first row of nozzles is aimed at the top of the transformer casing to extinguish flames from the pooling transformer oil on the top of the transformer casing.

A second row is installed as shown to protect the sides of the transformer casing, extinguishing the cascading fire. Foam accumulation in the curb will handle the burning oil by covering the surface. Other nozzles as shown are located to properly cover the shape of the oil expansion tank.

Figure 1

Detail of the nozzles grid around a typical transformer

As shown in Figure 2 (see below), the resulting balanced flow piping is much simpler to install and of smaller diameter than the equivalent deluge grid system, reducing the costs for the installing contractor.

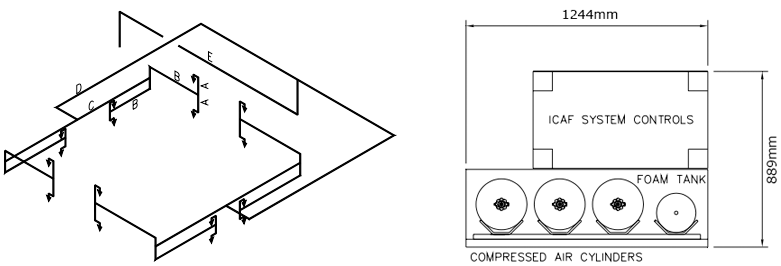

The ICAF System itself also has a small footprint (see Figure 3 below) and can even be skid mounted for more flexibility. The foam concentrate is stored in a non-pressurized tank of only 38L capacity and does not use bladders or complicated inductors and trims. The entire foam trim is actually factory-built in a user-friendly cabinet!

A bank of three high pressure compressed air cylinders is supplied to provide the pressure to the system so the existing water pressure can be used to feed the system.

Figure 2

3D view of a typical ICAF balanced piping grid

Conclusions

Fire protection designers now have an additional weapon in their arsenal of fire combat tools. The ICAF technology is emerging as an environmentally friendly solution for the protection of power transformers and other similar hazards.

Special considerations need to be taken with the nozzle layout for this kind of hazard since power transformer configurations vary. ICAF Systems are so efficient at extinguishing this type of fire, full-scale fire tests have demonstrated total suppression will be achieved three times faster than a typical deluge system!

With ICAF Systems installed in their power plants, utilities can now better protect their investment while achieving quicker and total suppression in case of accidental fires.

Should you have questions regarding this application or any other involving transformers, contact SIRON Compressed Air Foam. Our engineers will work the project out with you and find the best layout for your specific application.